Welcome to Our Garage

Daytona Coupe, 289 and 427 Cobras

-38-

Daytona Coupe Cobra -

Weber "System" Considerations

I have worked on my share of Holley 4 barrel carburetors, but this is the first for Webers. I will also say upfront that this section gives a few glimpses of the process I went through in setting up and tuning the Webers of my Daytona. My goal is to summarize a few of the key considerations and the basic process rather than attempting to provide an exhaustive step by step tutorial. There are many other sources of the specifics of Weber tuning available on the Internet. I have included links to a number of several helpful links at the end of this section.

Weber engine considerations:

Acording to the true Weber experts, there are several critical parameters that must be implemented on most every Weber installation. A successful installation must be looked at as a complete sytem and consideration must be given to several other parts. The following components in particular have a significant effect on the success of a Weber carburetor installation.

- Camshaft

- Fuel pressure

- Ignition timing

- Carburetor linkage

Camshaft:

First and foremost, the engine must have a camshaft that is Weber friendly. Without a suitable camshaft, tuning a Weber engine can become a difficult (bordering on impossible) exercise.

Diggging a little deeper into the cam criteria, the camshaft used with Webers should have a lobe separation angle between the intake and exhaust valves of between 110 and 115 degrees. This is due in large part to the fact that the Webers are mounted very close to the engine intake valves so there is not the dampening effect on the intake fuel / air charge that is present with a normal 4 barrel carburetor and manifold (with a plenum).

Fuel pressure:

Webers are very sensitve to the inlet fuel pressure. I have heard more "seasoned" Cobra guys say that many of the original Cobras running Webers did not utilize fuel pressure regulators. Whether pressure regulators were or were not used in the early days I do not know. Perhaps it was a case of simply not being aware of the carburetor's sensitivity to fuel pressure or simply the attitude that it was just a Weber idosynchroy.

Nowdays, a fuel pressure regulator that limits the fuel pressure to a maximum of 3.5 PSI is a standard component on virtually all good running Weber systems.

Ignition timing:

Webers like a lots of timing. The initial timing should be relatively hign and the distributor should be calibrated so the remainder of the centrifical advance timing comes in quickly. Again, according to others with more experience than me, an initial timing of approximately _____ BTDC with a total advance of approximately ______ BTDC all in by approximately __________RPM is a good rule of thumb.

Carburetor linkage - Two typical approaches

For proper operation, the linkage between the four carburetors must be designed and installed to be rigid and to provide exactly the same amount of butterfly opening to all carburetors at exactly the same time. I.e. all four carburators (and all 8 butterflies) must be syncronized to open and close in unison.

As indicated on a previous page, I have decided to use the GT350 style Weber manifold.

The linkage required is directly related to the manifold design being installed. In the case of the GT350 non-opposed manifold, the butterflys of all four carburetors rotate in the same direction.This obviously dicates the direction the linkage must rotate the carburetor butteryfly shafts.

There are three basic linkage configurations, each with pros and cons. The linkage choices are:

- Bellcrank style: This design utilizes a three arm "T" shaped bellcrank typically mounted about mid way (front to back) on the maniforld. One of the arms acutates the two driver side Webers and a second arm actuates the two passenger side carburetors. The third arm is connect to the acelerator pedal (most often with another bell crank located at the rear of the manifold) and a sheathed cable assembly. This design also requires the front and rear carbs to be interconnected as described below.

- Central shaft style: This alternative design utilizes a 5/16" diameter steel shaft running lengthwise from approximately the middle to the rear of the intake manifold. On the shaft are three vertically mounted lever arms. One lever acutates two Webers, but in this design, the carbs are "paired" as front driver and front passengers side carburetors. A second lever similarliy drives the other "paired" carbs; rear driver and rear passenger carbs. The third lever is connected directly to a sheathed cable assembly for operation by the acceleraor pedal.

- Central shaft alternative: This alternative design is a combination of features of the Bellcrank" design and the Cental shaft design. It uses two vertical levers and the front to rear carb interconnections linkage. One vertical lever to drives the passenger front and rear carburetors as well as the driver side front and rear pair. The second lever provides the acelerator pedal cable drive point connection.

Intercarb connecting linkage. The Bellcrank design (as well as the central shaft alternative design) requires the butterly shafts of the front and rear Webers be actuated from one point. Weber offers an intercarburetor linkage (often called a "pin and paw") which connects the front and rear carburetor shafts of an inline carburetor pair. With the left side carburetors interconnected and the right side carburetors interconnected, it allows each front and rear pair to be driven with only one linkage connection to the bellcrank (or the central shaft).

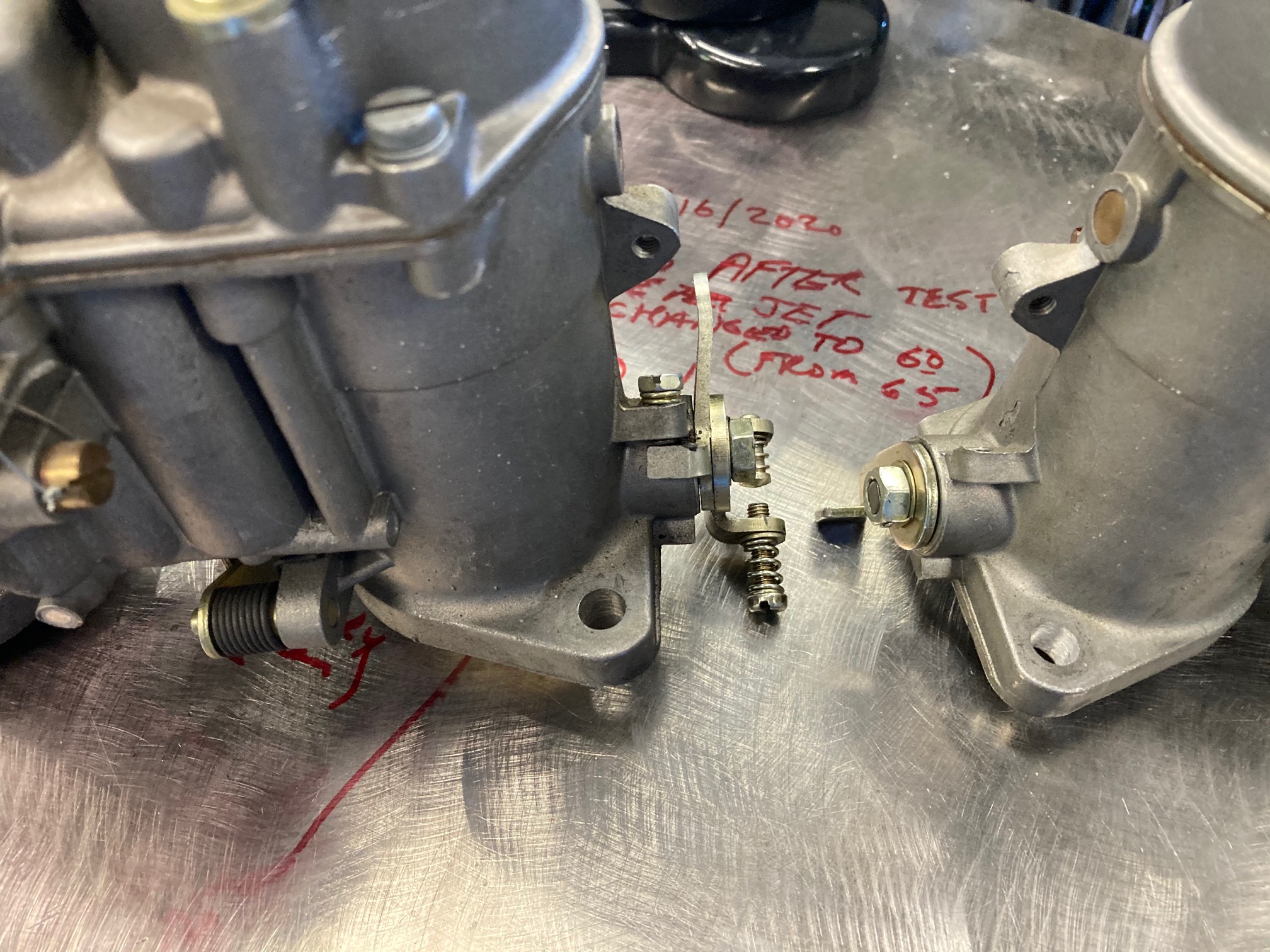

The "paw" on the left carburetor (the two opposing spings and adjustment screw) and the "pin" on the right (the approximately 1/4" square flat portion) are clearly shown in the photo below. The orientation of the carburetors in this photo is to more clearly view the pin and paw linkage and is not the way they are installed on the engine.

The following photo shows the carburetors as they are actually oriented when installed on the engine. When mounted on the manifold, the carburetors are close enough together that the pin (shown on the lower carb) fits into the paw (shown on the upper carb).

The final piece of the linkage story is how the accelerator pedal is connected to the manifold mounted linkage (either the Bellcrank style or the Central shaft style). Cobra roadsters (both 289 and 427) had the accelerator pedals mounted to the top of the driver fooot box, making it relatively easy to use a small shaft to connect with the carburator linkage. Because the acceleraor pedal is floor mounted on the Daytona, a different approach was needed. All (or at leat most) of the original Daytonas utilize a sheathed cable as the connection between the accelerator pedal and the engine mounted linkage.

The bottom line when it comes to the Weber details on the Daytona, is the common theme; they were all initially slightly different and likely were "tweeked" even from race to race. From the photos that I have seen, it appears that all of the originals utilzed the Central shaft design (none of the original cars appear to have used the center bellcrank design which was more common on the Cobra roadsters and the GT350 Mustangs). However, it also appears that some Daytonas utilized the intercarburator linkage (driven from the central shaft and two links) and some used the individual carburator drive approach (with four links from the central shaft.)

Helpful Weber links:

- Jim Englese's "Weber Tech" page. Jim has been working on Cobra Webers since the early days and is one of the most knowledgable in the business. His Weber Tech page is a great introduction to the 48 IDA Weber.

- Pierce Manifolds "48 IDA Exploded View" page: Pierce Manifold sells parts for 48IDA Webers, as well as providing technical information. Particularily helpful is the 48 DA exploded view that is linked to the actual Weber part number.

- Club Cobra "Weber Tuning Forum": This forum includes years worth of questions and responses by Cobra entusiasts and experts covering virtually everthing you might want to know on the Webers for Cobras.

- Tim's Cobra Roadster "Tuning Webers" page: Although not updated in some time, Tim has provide a great overview of the 48 IDA Webers as installed in a replica Cobra and how other enthusiasts might consider working through the tuning process.